Wind turbine internal blade inspection report processing solution

Background

Our end client is a multinational wind engineering company Siemens Gamesa Renewable Energy S.A. Today this subsidiary organization of Siemens Energy AG is a leading supplier of wind power solutions to customers all over the globe. It manufactures wind turbines and provides onshore and offshore wind services being the world's second largest wind turbine manufacturer. A wind turbine is a complex mechanism that requires constant maintenance and inspection. At the same time, the process of such assessment is multi-level, complicated, and time-consuming. The customer wanted to optimize the routine and asked to create a cloud-based web application that will replace the manual processing of turbine inspection files. This solution was to be one of the cornerstones of a big project related to automation of identifying findings in the customer's turbines.

| Product | Web platform for wind turbines internal blade inspection |

| Client | Siemens Gamesa Renewable Energy S.A. |

| Vertical | Wind energy |

| Buyer persona | Subcontractor responsible for blade inspection solution |

| Technology | .NET Framework, .NET Core, Angular, AWS, 3S Buckets, DynamoDB, Docker Container, Lambda Function |

| Provided services | Application development, AWS configuration |

Goals and Challenges

Before describing the technical solution, it is important to dive into the turbine inspection process itself.

Usually, the assessment process is identified with the inspecting of one of the main structural parts of the turbine mechanism, i.e., blades that are constantly exposed to wind, gravity, and centrifugal loads. Blades are the most expensive components of a wind turbine, so timely detection of defects in blades increases system reliability as well as blade lifespan and enables more efficient condition-based maintenance; repairs can occur before more extensive damage levels are sustained, minimizing turbine downtime.

Each turbine manufactured by SGRE has three blades. Their inspection begins with a blades assessment by Wind Turbine Technicians who work at the turbine locations. To analyze the blades, the staff conducts an internal and external review of the structure, recording its condition in photos. Then a technician prepares a report in PDF format with pictures, text, and technical details of the inspected blade. Each turbine blade has its separate report.

Once the report is created on location, it gets to the company's engineers, who verify it, analyze and give their recommendations for further work with each particular blade. Before using the implemented solution, this process on the client's side was completely manual. The data was not structured, kept scattered, and was growing up like an avalanche. Something had to be done about it.

To overcome all the limitations of the workflow mentioned above, it was decided to create a separate web application, a single center for data storage and inspection analysis. In other words, it was planned to develop a portal for SGRE engineers.

Solution

The application was built as a Serverless Web Application based on Amazon services. To create comprehensive architecture, the following AWS-components have been used:

- 3S Buckets;

- DynamoDB;

- Docker Container;

- Lambda Function.

Also solution contains .NET Core based projects for parsing PDF files and providing Web Api for admin portal. Front-end is built using Angular.

The work with the system can be divided into several stages. After the initial reports are generated by the company's technicians, they are transferred to the engineers, who are the end users of the system. Next, each user manually uploads the PDF file to the S3-Bucket. The application allows you to process several files at a time.

When a PDF file is downloaded in the cloud, a Lambda function triggers the PDF-extractor that extracts the images and text. Images are stored back in the S3-Bucket and text data is stored in DynamoDB.

Once the report data is in the system, you can start working with it. To conclude, the user looks through all the report data and leaves their comments, both on the text part and directly on the graphic elements (photos of blades). For example, if the damage is detected, the user can specify the damage rank, damage type code, etc. In the final part, the expert creates a conclusion and annotation for the report.

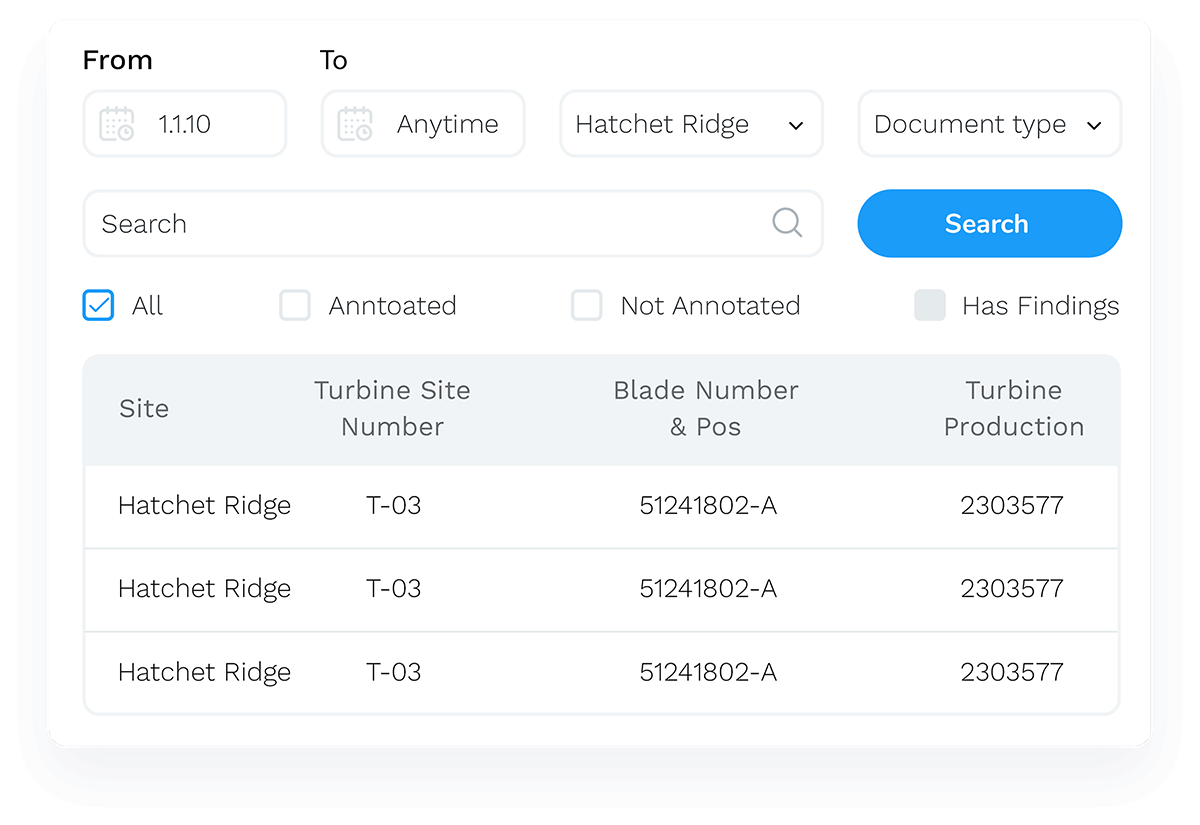

The second significant advantage of systematizing and reports’ digitizing became the ability to search for similar cases and damages in the database. For this purpose, we developed a search system with advanced filtering and display of primary data, both by turbine model and by inspections performed.

The data found can be exported in various formats to compile statistics on the number of identified findings or types of findings, for instance.

Results

Of course, the main result is the creation of a fully working сloud-based solution with rich search functionality, filtering and administration user interface, with a possibility of data classification and automated PDF processing. However, it’s only a tip of the iceberg.

This solution is one of the key components in a larger Siemens Gamesa project related to automation of detecting potential blade damages. It uses ML technology and the data about more than 50.000 blades maintained and 20 years of blade maintenance data to identify and assess findings.